One of the most aggravating and dangerous things for a crane operator to do is operate the crane blindly. Until recently, this involved having to drive the crane, make the lift, pick up the load, and drop the load without having any way to see the load. The only way that a crane operator could make sure that the load was secure and placed in the right location was by depending on communication with the riggers below. This was often done with hand signals and radio communication. Unfortunately, both of these methods could often be inaccurate, making every blind lift more dangerous and less productive. Loads could be lost if they were not secured correctly, or if they were not placed correctly. Thanks to HoistCam’s cameras on cranes, the accuracy of load placements can now be increased a great deal, thus increasing efficiency and productivity. Let’s learn how.

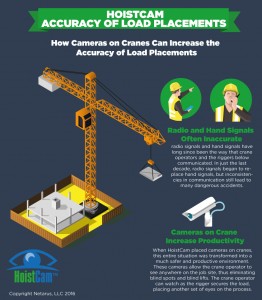

Radio and Hand Signals Often Inaccurate

As mentioned, radio signals and hand signals have long since been the way that crane operators and the riggers below communicated. In just the last decade, radio signals began to replace hand signals, but inconsistencies in communication still lead to many dangerous accidents. These accidents often caused loss of life, and loss of property. When a load is not secured properly, or placed properly, the results can be devastating.

According to retired crane operator Duffy L Best, blind lifting is “one of the most dangerous things we do with a crane.” Best went on to explain what a nightmare it can be for the crane operator when the communication between himself and the rigger is flawed. If a crane operator cannot understand the signals coming from his riggers, he will often shut down the whole operation until the issue is resolved. This necessary safety measure leads to a huge time loss for the entire company. Fortunately, cameras on cranes by HoistCam can completely eradicate this entire issue.

Cameras on Crane Increase Productivity

When HoistCam placed cameras on cranes, this entire situation was transformed into a much safer and productive environment. These cameras allow the crane operator to see anywhere on the job site, thus eliminating blind spots and blind lifts. The crane operator can watch as the rigger secures the load, placing another set of eyes on the process. This helps to make sure that nothing is missed and no mistakes are made. The operator can also watch see the load as it is picked up, and as it is placed via a monitor that sits inside of the cab with him. This monitor is fed from the camera, giving the operator a bird’s eye view of the entire lift, from start to finish.

It is easy to see why this would be ideal. By giving the crane operator the ability to see the entire lift, you drastically cut the chances of accidents, and increase efficiency and productivity of every lift. Each lift takes much less time to complete, meaning more lifts are performed each day. By reducing the chance of accidents, you not only help ensure the safety of your crew, but the accuracy of your load placements as well. Contact us for more information on how cameras on cranes can increase the accuracy of load placements.