HoistCam provides multiple options for rail cars, trains and locomotives from steel mills and chemical plants to intermodal and rail handling yards. The HoistCam system is designed to be easy to install, eliminate blind spots, increase safety, and improve productivity for the locomotive engineer from inside of the train or from a control station.

HoistCam has been found to reduce incidents by over 90% and increase productivity by 20%+. Learn more and view the HoistCam Case Studies>>.

Compatible Platforms: i-Series, HD147, HD147i, HD187, HD187i, HD197, HD197i, HD107, HoistCam Director

HoistCam in a Rail Handling Yard

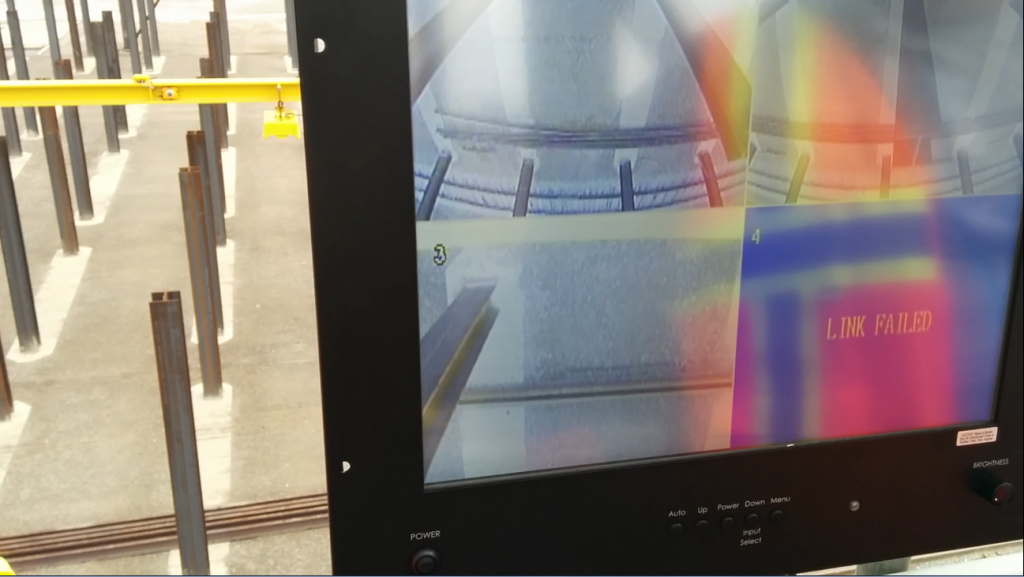

HoistCam is used on a magnetic lifting system in a rail handling yard where the operator to see during that blind lift. HoistCam can be repositioned as needed in a matter of seconds, or be located anywhere else in and around the yard.

HoistCam overhead crane camera system can be powered by the overhead crane directly or rechargeable batteries can be used to make installation more convenient. HoistCam is stored in a suitcase size transport case that makes it easy to move between facilities or relocated to a different overhead crane.

HoistCam can be tied into a remotely accessible interface called HoistCam Director to monitor and track an a yard from a centralized operations center or any desktop PC. In addition, multiple HoistCam’s can be deployed and viewed through a split screen in the operator’s cab or control room for additional visibility around the facility.